Creek Pipe local contractor: Why regulatory alignment matter

Wiki Article

Maximizing Cost-Effectiveness With Advanced Pipeline Solutions: a Comprehensive Guide

In the developing landscape of pipeline administration, organizations are increasingly seeking ways to enhance cost-effectiveness. Advanced pipeline services use a variety of remedies that guarantee boosted functional efficiency and minimized maintenance expenditures. Nonetheless, the assimilation of new innovations and techniques provides both possibilities and difficulties. Comprehending these components is crucial for maximizing the advantages. What particular strategies can organizations take on to navigate this complicated setting?Comprehending Advanced Pipeline Solutions

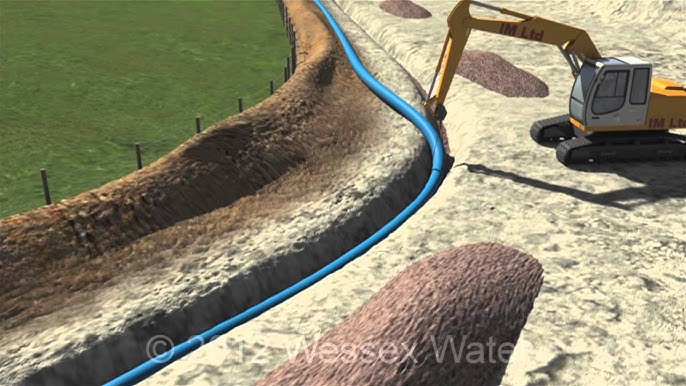

As sectors increasingly rely upon reliable fluid transport systems, recognizing advanced pipeline solutions becomes important. These solutions encompass a variety of tasks, consisting of the design, building and construction, upkeep, and operation of pipeline networks. Business associated with innovative pipeline solutions concentrate on maximizing efficiency and ensuring security, typically using specialized understanding and techniques to manage complex systems.One important aspect is the assessment of pipeline integrity, which entails routine inspections and keeping an eye on to find prospective concerns prior to they escalate. Furthermore, the application of advanced products and construction techniques boosts longevity and minimizes environmental impact. Correctly carried out pipeline services add to minimized downtime and functional expenses, making them critical for businesses in industries such as oil, gas, and water circulation. Inevitably, a detailed understanding of these services enables firms to make educated choices, making sure the smooth movement of fluids while adhering to regulative standards and market finest techniques.

Trick Technologies Driving Cost-Effectiveness

Numerous key modern technologies are improving cost-effectiveness in advanced pipeline services. Automation stands apart as a crucial vehicle driver, making it possible for remote surveillance and control that lowers labor prices and reduces human error. The combination of Net of Points (IoT) gadgets enables real-time data collection, helping with positive decision-making and maximizing source allowance. Advanced products, such as composite pipelines, are increasingly utilized for their durability and resistance to corrosion, leading to reduced substitute and upkeep expenses in time.Additionally, data analytics plays a considerable duty in determining ineffectiveness and anticipating potential failings, allowing for targeted treatments rather than covering upkeep approaches. Additionally, artificial intelligence algorithms can boost anticipating upkeep designs, even more lowering functional expenses. Together, these technologies cultivate a more efficient and cost-effective strategy to pipeline administration, making sure that operators can maximize their financial investment while keeping safety and conformity criteria

Techniques for Decreasing Upkeep Costs

Executing effective techniques for reducing upkeep expenses in pipeline solutions is necessary for improving overall functional efficiency. Among the main methods includes adopting anticipating maintenance methods, which leverage information analytics to anticipate concerns before they rise. By using sensing units and monitoring systems, operators can identify possible problems, enabling for timely interventions that decrease costly fixings.Another crucial strategy is to systematize tools and elements, which streamlines stock monitoring and decreases training prices for maintenance workers. Normal training programs also equip team with the required abilities to carry out upkeep jobs much more effectively.

Enhancing Security Standards in Pipeline Administration

While the assimilation of sophisticated modern technologies in pipeline monitoring has considerably boosted operational effectiveness, boosting safety requirements remains an essential priority. Business have to implement extensive safety and security protocols to reduce dangers related to pipeline operations. Routine assessments, making use of both drones and smart sensors, can determine possible dangers before they rise right into substantial issues.Training personnel in emergency action and safety procedures additionally adds to a more secure working atmosphere. Furthermore, taking on durable surveillance systems help in the early discovery of leakages or architectural weaknesses, allowing for timely treatments.

Furthermore, compliance with sector laws and ideal techniques warranties that safety measures are not only reliable yet additionally standard across operations. Engaging with stakeholders, including neighborhood areas, promotes transparency and builds trust, boosting general security assumptions.

Eventually, focusing on safety in pipeline monitoring not just safeguards personnel and the setting but additionally aligns with cost-efficient functional approaches.

Enhancing Operations for Greater Effectiveness

Optimizing pipeline procedures requires a critical strategy that lessens waste and makes best use of efficiency - Midland oilfield pipeline services. By executing innovative technologies such as automation and information analytics, companies can improve their functional efficiency. These devices make it possible for real-time surveillance of pipeline conditions, enabling prompt treatments that stop pricey downtimeStandardizing processes additionally adds to streamlined procedures. By taking on constant methods for maintenance and assessments, companies can reduce variability and enhance integrity in their pipeline solutions. Additionally, worker training plays an essential role; knowledgeable personnel are better outfitted to execute tasks successfully and securely.

Partnership with seasoned provider can use added insights into best practices, allowing firms to fine-tune their functional structures. Eventually, a focus on continual improvement guarantees that pipeline procedures remain agile and responsive to changing needs, cultivating lasting sustainability and cost-effectiveness in the sector.

Regularly Asked Inquiries

What Credentials Should I Try to find in a Pipe Solutions Company?

When picking a pipe providers, one must think about certifications such as market certifications, experience, safety records, technical experience, consumer recommendations, and conformity with regulative standards to assure dependable and efficient find more service distribution.Exactly How Can I Assess the ROI of Advanced Pipeline Solutions?

To assess the ROI of sophisticated pipeline solutions, one ought to assess expense financial savings, effectiveness renovations, and enhanced revenue generation. Comparing these metrics versus first investments and recurring operational costs will certainly provide a more clear economic image.Are There Any Kind Of Industry Accreditations for Pipeline Solution Technologies?

What Are the Environmental Impacts of Advanced Pipeline Providers?

Exactly How Commonly Should Pipeline Equipments Be Reviewed for Performance?

Pipeline systems need to be evaluated for efficiency at the very least yearly (Midland oilfield pipeline services). Normal analyses aid recognize possible concerns, maximize efficiency, and assurance compliance with policies, eventually contributing to enhanced reliability and reduced functional prices in the long runReport this wiki page